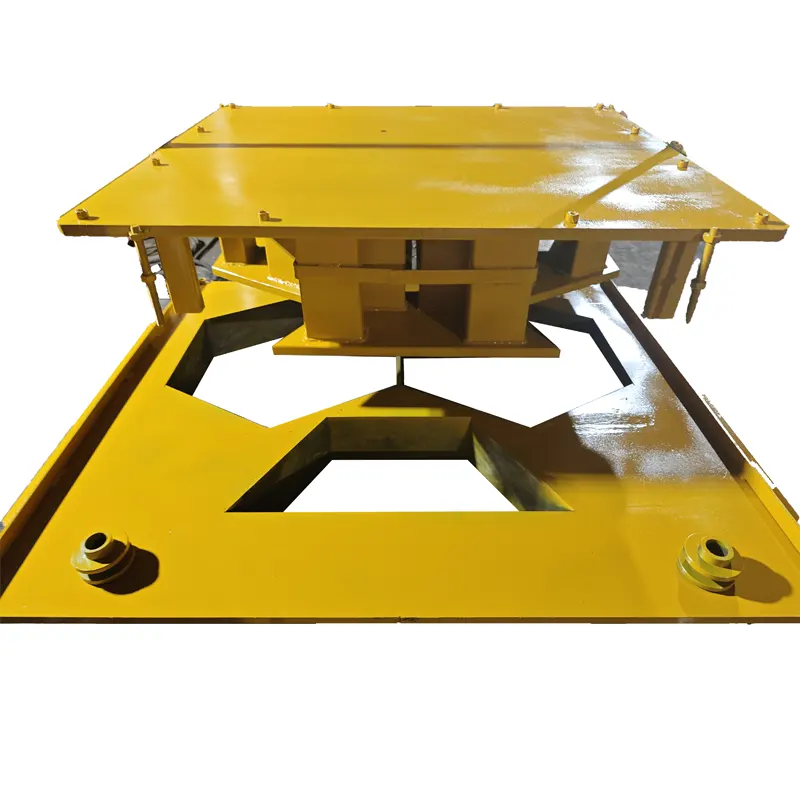

Paving Brick Molds

Discover SOTOP’s Paving Brick Molds, expertly crafted for precision and durability by SOTOP Machinery Solutions, a leading paving brick molds manufacturer and wholesale supplier with a global presence across over 40 countries. These molds enable the production of high-quality paving bricks for driveways, patios, and walkways, offering customizable designs, factory-direct pricing, and supported by our localized after-sales service for seamless integration with brick-making machines.

Ready to Elevate Your Brick Production?

If you have questions or need more information about our brick machines, we’re here to help! Our team is ready to assist you in finding the perfect solution for your needs.